The best finishes to enhance natural stones

Some types of finishes can be used to give a new accent to the stone, giving it a special aesthetic feature, or just to make it suitable for outdoor use. In this article we explore some of these types.

Flaming

Flaming is a technique that is performed by exposing the stone surface at very high temperature using a blowtorch. The stone is then immediately cooled with water and the thermal shock causes the detachment of small parts. This process underlines the structure and the natural colour of the material, giving the surface a rough and vitrified aspect.

The flaming is suitable for all granites and some marbles and is particularly suitable for outdoor use as it makes the material anti-slip and more resistant to atmospheric agents.

Hydrofinish (water flame)

Hydrofinish is an innovative system for the treatment of slabs which consists in processing the surface with powerful jets of water, obtaining an effect similar to the flaming.

This process gives to the material different kind of roughness, depending on the intensity of the water jet with which it is treated, and exalting its original colour.

Hydrofinish is applicable to granites and some marbles..

Natural Split finish

This finish is nothing more than the natural aspect of the split stone and is obtained by putting pressure along the breaking lines of the stone block, so it separates naturally.

The surface obtained in this way is much rougher than those obtained with other types of finish, resulting perfectly anti-slip.

It is mainly used on outdoor stones, floors and wall coverings. Only some stones, as slate and lava stone, can be processed with this finish.

Raw finish

This type of finish is applicable to marble or granite and is obtained by cutting the block with a diamond saw. The obtained surface has a rough and irregular aspect, while the colours of the material remain unchanged. The stones with this finish are ideal for outdoor floor.

Scratching finish

Scratching finish consists in exposing the surface to an abrasion process using special rotating tools. The result is a rough, scratched stone.

This technique is particularly suitable for materials with a uniform shade and fine grain, such as slates, sandstones and marbles.

Bush hammering

The bush-hammered finish is obtained by an impact process, using a pneumatic or manual percussion instrument with steel tips.

The final result is a rustic but homogeneous effect. The stones with this finish are mainly used for outdoor floor, thanks to its durability and anti-slip characteristics.

Bush-hammering can only be performed on some types of marble and granite.

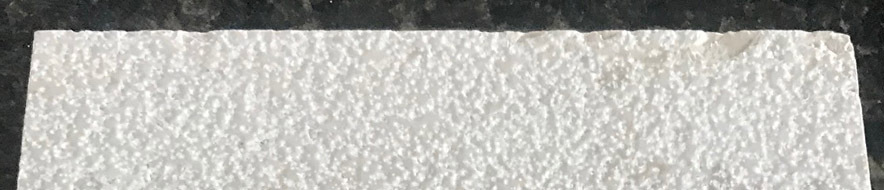

Sandblasting

The sandblasted finish is obtained by using a high pressure jet of sand that smoothes the edges of the stone and makes the surface rough and matt, with good anti-slip properties. For this reason, the sandblasted stones are ideal for outdoor areas or wet areas.

Not all the stones can be subjected to this process, as it cannot be applied to too soft or irregular materials.

Special finishes

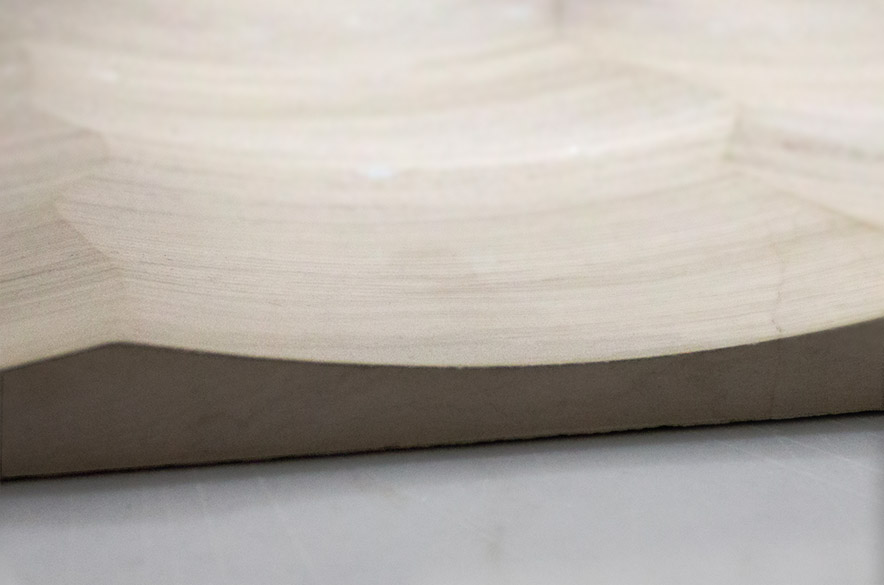

In addition to these classic finishes, there are others that give a more particular texture to the material, such as striped, juta, bark and tranchè. These finishes are recommended for enriching materials with a flat surface and few veins.

Depending on the effect you intend to achieve and the material that will be used, some finishes may be more suitable than others. Request our free advice to find the right finish for your next project.

No Comments